Since 20 years we rely on the System of LAETUS® for that tasks. Due to our convincement for this devices we also acting as distributor for Laetus in Austria and Hungary. Laetus offers a suitable solution for nearly all inspection purposes. Simply select your application and check out which devices can handle your inspection task.

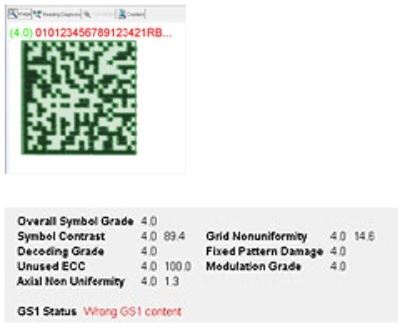

Identification using bar code/2D code 1D and 2D codes are utilized in virtually all industrial sectors to identify products and to record data. The coding enables each individual product to be identified.

Crucial for the quality of product packaging is not only its intactness but also the completeness of its contents. There is a wide range of presence monitoring for this purpose.

Tubes must be oriented in the filling line before closure so that the seam can always be placed precisely. This allows the orientation to take place based on the print marks or the pharmacode.

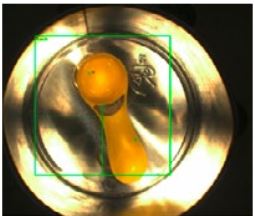

Color evaluation can check whether, for example, a dosing spoon is present but also whether the correct color has been enclosed. This application is also suitable for caps, information leaflets and canulas.

Inspecting the print quality is an essential part of quality assurance for product packaging. Evaluations are made based on given standards (e.g., ISO/IEC 15415 (2D code) or ISO/IEC 15416 (1D code).

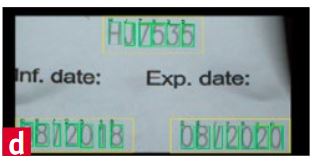

In addition to codes, packaging also includes nu-merous additional information in plain text, such as product or company information or logos, pictograms, and other symbols. Print inspection of this information is carried out using OCR/OCV reading.

Controlling the right position of packaging compo-nents and labels is an important part of quality control. Numerous criteria can be inspected.

Increasing quality and safety requirements mean it is necessary to check for further criteria in addition to simply the presence inspection. Irregularities can occur when filling pharmaceuticals in blisters, which can have relevant impacts on the quality.

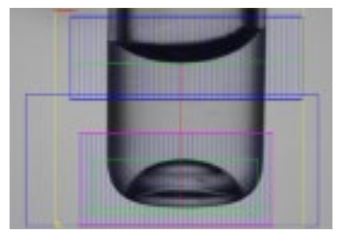

Controlling the correct fill level is an import quality criterion. In the pharmaceutical and food industries in particular, the fill level control provides reliable packaging processes.